Air generation and treatment : compressed air, a fluid with multiple challenges

Technical expertise: asset to efficient action

Currently, the energy cost is a main determinant of investment in a compressed air system. Our technicians will assist and provide you with advice on efficient latest technology solutions.

- Lubricated and non-lubricated screw compressors, pistons and pallets

- TURBO Oil free compressor class 0

- SCROOL Oil free compressor

- HP compressor

- Vacuum pump

- Calories boiler

- Filtration

- Dryer

- Condensate treatment

- Oil drain

- Tank

- Nitrogen generator

- Breathable air

- Air and nitrogen network TRANSAIR

ACE Services

- Extend the lifetime and reduce maintenance costs of your equipment.

- Upgrade your equipment and your compressed air network.

- Reduce your energy consumption.

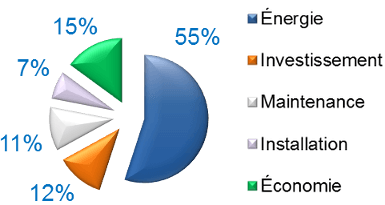

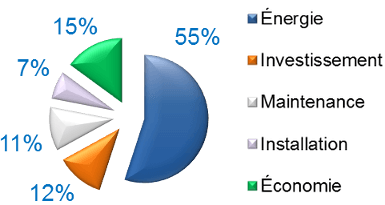

Equipment distribution of expenses within 5 years’ period

Services

- Audit consumption and energy efficiency

- On-site service and repairs

- Service contract

- C2E / LOA file creation

- Technical requirements

Measurement and Analysis

- Humidity (dew point + 20 ° C to -70 ° C) with psychrometer, data recording possibility

- Flow rate up to 720 m3 / h (direct measurement or recording over a period)

- Tanks, pressure testing up to 500 bar (2 blowers with equipment)

- Ultrasound (leaks checking)

- Vibrators (screw block and electric motor)

Checking

- Valves: control and revision with maximum setting to 435 bars

- Air quality following the standard NF / EN 12021

- Annual leakage of refrigerant circuit under Decree No 2007-737 of 07/05/07